Milestone group leads in lean manufacturing with a skilled engineering team using advanced design software to develop precision transmission components for multiple sectors.

Milestone Gears is equipped with MPM HUTA hammers: 1 Ton, 2.5 Ton, 3 Ton & 5 Ton and Upsetters: 4”, 6” & 7.5” (800 to 1500 ton), fed with Induction bar heating and controlled by temperature based accept/reject mechanism to ensure thorough heating & temperature gradients.

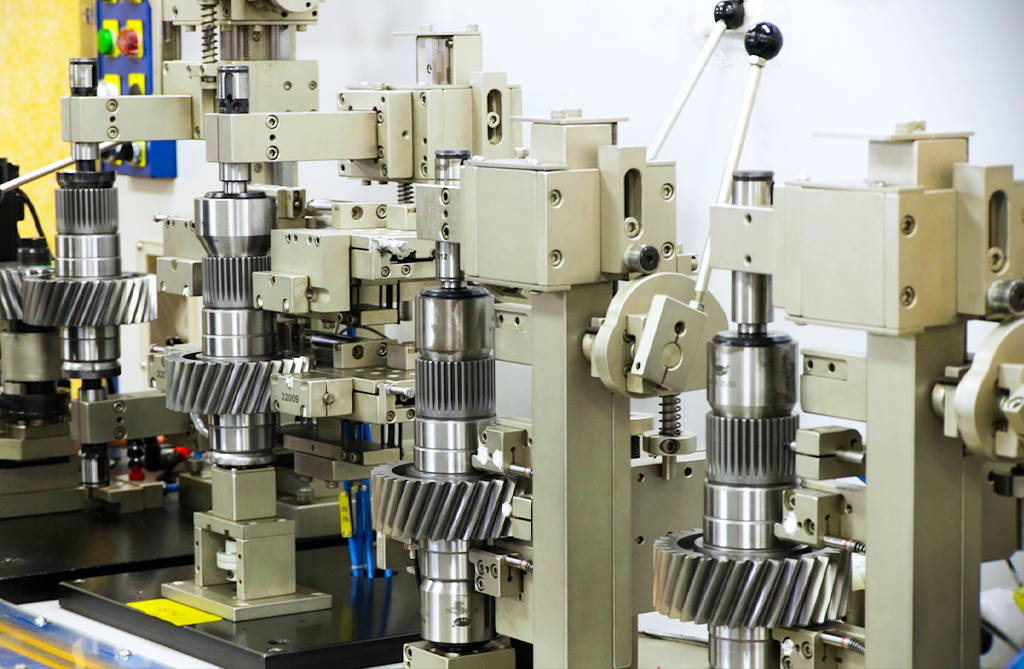

Milestone Gears boasts over 375 advanced CNC machines, capable of producing precision gears up to 1500 mm diameter and shafts up to 1500 mm length.

CQI-9 Compliant Heat Treatment Processes,

Seal Quench Furnaces, Gas Carburizing Furnaces, Press Quench and Cryogenic Treatment Chambers complimented with shot peening and glass peening.

Quality starts at the gate! - All incoming steel is subjected to our stringent Metallurgical Standards & Testing. Our End-to-end material testing infrastructure features advanced cutting, moulding, sample polishing and preparation integrated with advanced inspection tools like spectrometers, portable XRF, high resolution microscopes and ultrasonic test machines.

Milestone Gears ensures unmatched accuracy with 5-axis CNC gear analyzers, 3D CMM, Video Vision Optical Measuring Systems, Automated Gear testers, Closed loop feedback systems providing precise machining and validation of gear dimensions.

Early adopters of German Patented Scudding Technology for Internal Ring Gears with a significant concentration of Scudding machines in India

Milestone Gears Ltd. is committed to social responsibility through Nai Shuruwat, a charitable trust. Since 2011, the trust has been working to empower women affected by domestic violence, improve healthcare access and enhance educational opportunities in underserved rural and tribal communities.

At Milestone Gears, our foundation is built on precision, innovation and integrity. We promote a culture of continuous learning and hold ourselves to high standards of accountability, ensuring a healthy and professional work-life balance. We are united by a strong sense of teamwork, using advanced technology to deliver quality that consistently meets world-class standards.

Disclaimer – Important

PLEASE READ THIS NOTICE CAREFULLY. IT APPLIES TO ALL PERSONS WHO VIEW THIS WEBSITE. THESE MATERIALS ARE NOT DIRECTED AT OR INTENDED TO BE ACCESSED BY PERSONS LOCATED OUTSIDE INDIA. THESE MATERIALS ARE BEING MADE AVAILABLE ON THIS WEBSITE TO COMPLY WITH SECURITIES AND EXCHANGE BOARD OF INDIA (ISSUE OF CAPITAL AND DISCLOSURE REQUIREMENTS) REGULATIONS, 2018, AS AMENDED.

Investors should read the Draft Red Herring Prospectus and seek professional advice before taking any action.

IMPORTANT: You must read and agree with the terms and conditions of the following disclaimer before continuing.

The following disclaimer applies to the draft red herring prospectus of Milestone Gears Limited (the “Company”) dated November 18, 2025 (the “Draft Red Herring Prospectus” or “DRHP”) filed with the Securities and Exchange Board of India (“SEBI”) and BSE Limited and National Stock Exchange of India Limited (collectively, the “Stock Exchanges”), hosted on this website in connection with the initial public offering of the equity shares of the face value of of ₹2 each (“Equity Shares”) of the Company (the “Offer”). You are advised to read the following notice carefully before accessing or making any other use of the Draft Red Herring Prospectus. In accessing the Draft Red Herring Prospectus, you agree to be bound by the following terms and conditions, including any modifications to them from time to time.

Access to the Draft Red Herring Prospectus does not constitute a recommendation by the Company, the members of the Syndicate (as defined in the Draft Red Herring Prospectus) or any of their respective affiliates or any other person to subscribe to the Equity Shares offered in the Offer.

The Draft Red Herring Prospectus is directed at, and is intended for distribution to, and use by, residents of India only. The information in this portion of our website, including the Draft Red Herring Prospectus, is not for publication or distribution, directly or indirectly, in or into the United States. The contents of the Draft Red Herring Prospectus is for your information only, and you acknowledge that access to the Draft Red Herring Prospectus is intended for use by you only and you agree not to forward the Draft Red Herring Prospectus on to any other person, internal or external to your company, in whole or in part, or otherwise provide access via e-mail or otherwise to any person. Any person into whose possession the DRHP comes is required to inform himself or herself about and to observe any such restrictions. BRLMs and/or its affiliates or their respective directors, officers and employees are not soliciting any action based on any of the information contained on this website, including the DRHP, and such information should not be construed as an offer, or invitation or offer to sell or the solicitation of any offer to buy or subscribe for or purchase any security. No part of the contents of the Draft Red Herring Prospectus shall be copied or duplicated in any form by any means or redistributed.

The Draft Red Herring Prospectus has been hosted on this website as prescribed under Regulation 26(1) of the Securities and Exchange Board of India (Issue of Capital and Disclosure Requirements) Regulations, 2018, as amended. Our Company has taken all necessary steps to ensure that the contents of the Draft Red Herring Prospectus as appearing on this website are identical to the Draft Red Herring Prospectus filed with the SEBI. You are reminded that documents transmitted in electronic form may be altered or changed during the process of transmission and consequently, neither the Company nor JM Financial Limited, Axis Capital Limited, Motilal Oswal Investment Advisors Limited (the “Book Running Lead Managers” or the “BRLMs”) or any of its affiliates accepts any liability or responsibility whatsoever in respect of alterations or changes which have taken place during the course of transmission of electronic data.

The Draft Red Herring Prospectus does not constitute an offer to sell or an invitation to subscribe to the securities offered in any jurisdiction to any person to whom it is unlawful to make an offer or invitation in such jurisdiction and is not intended for distribution to, or use by, any person or entity in any jurisdiction or country where (a) distribution or use of such information would be contrary to law or regulation; or (b) the Company or any of its affiliates would by virtue of such distribution become subject to new or additional registration, licensing or other regulatory requirements. The Equity Shares offered in the Offer have not been and will not be registered under the U.S. Securities Act of 1933, as amended (“U.S. Securities Act”) or any state securities laws in the United States, and unless so registered, may not be offered or sold within the United States, except pursuant to an exemption from, or in a transaction not subject to, the registration requirements of the U.S. Securities Act and in accordance with any applicable U.S. state securities laws. Accordingly, the Equity Shares are being offered and sold only outside the United States in ‘offshore transactions’ in compliance with Regulation S under the U.S. Securities Act and the applicable laws of the jurisdictions where such offers and sales are made.

Any person into whose possession the Draft Red Herring Prospectus comes is required to inform himself or herself about and to observe any such restrictions. Neither the Company, BRLMs nor any of its affiliates is soliciting any action based on the Draft Red Herring Prospectus, and it should not be construed as an offer to sell or the solicitation of an offer to buy any securities. Potential investors should not rely on the Draft Red Herring Prospectus for any investment decision.

Any decision on whether to invest in the equity shares described in the Draft Red Herring Prospectus may only be made after a red herring prospectus has been filed with the Registrar of Companies, Himachal Pradesh at Chandigarh and the SEBI and must be made solely on the basis of such red herring prospectus, as there may be material changes in the red herring prospectus compared to the Draft Red Herring Prospectus. Invitations to subscribe to or purchase the equity shares in the Offer will be made only pursuant to the red herring prospectus if the recipient is in India or the preliminary offering memorandum for the Offer, which comprises the red herring prospectus and the preliminary international wrap for the Offer, if the recipient is outside India. No person outside India is eligible to Bid for equity shares in the Offer unless that person has received the preliminary offering memorandum for the Offer, which shall contain the selling restrictions for the Offer outside India.

Any potential investor should note that investment in equity shares involves a high degree of risk and for details relating to such risk, please see the section titled “Risk Factors” of the red herring prospectus, when available.

Investors are advised not to rely on any other document, content or information provided on the Offer on the internet / online websites/ social media platforms / micro-blogging platforms and by the influencers since the same is not approved/ commissioned/ paid by the Company or its promoter(s)/directors/KMPs in any manner. Investors are advised to rely only on the information contained in the Red Herring Prospectus and the price band advertisement for making investment decision.

You are accessing this website at your own risk and it is your responsibility to take precautions to ensure that it is free from viruses. Neither the Company, the Promoters, the Book Running Lead Managers nor their respective affiliates, directors, officers, agents, representatives, advisers or employees will be liable or have any responsibility of any kind for any loss or damage that you incur in the event of any failure or disruption of this website, or resulting from the act or omission of any other party involved in making this website or the data contained therein available to you, or from any other cause relating to your access to, inability to access, or use of this website or the Draft Red Herring Prospectus.

Neither the Company, BRLMs, nor any of its affiliates will be responsible for any loss or damage that could result from interception and interpretation by any third parties of any information being made available to you through this website. The Company and the Book Running Lead Managers cannot and do not guarantee the accuracy, timeliness or completeness of the information being made available to you in the Draft Red Herring Prospectus beyond the date of the Draft Red Herring Prospectus. The information contained in the Draft Red Herring Prospectus may not be updated since its original publication date and may not reflect the latest updates. The Company and its affiliates will not be responsible for any loss to any person or entity caused by any shortcoming, defect or inaccuracy which may have inadvertently or otherwise crept into the website. Neither the Company, any of its affiliates nor their directors, officers and employees will be liable or have any responsibility of any kind for any loss or damage that you incur in the event of any failure or disruption, shortcoming, defect or inaccuracy which may have inadvertently or otherwise crept into the website, or resulting from the act or omission of any other party involved in making this website or the data contained therein available to you, or from any other cause relating to your access to, inability to access, or use of the website or these materials.

If you are not permitted to view the materials on this website or are in any doubt as to whether you are permitted to view these materials, please exit this webpage.

To access this information, you must confirm by pressing on the button marked “I Confirm” that, at the time of access you are located and resident in India. If you cannot make this confirmation, you must press the button marked “I Do Not Confirm”.

The documentation contained in these pages is posted solely to comply with Indian legal and regulatory requirements. Making the information contained herein available in electronic format does not constitute an offer to sell, the solicitation of an offer to buy, or a recommendation to buy or sell securities of the Company in the United States or in any other jurisdiction, including without limitation, India.

[I Confirm] [I Do Not Confirm]

[If the viewer clicks “I confirm”, they should be taken to page 3; if they click “I do not confirm”, they should be directed away from the DRHP to a screen that says “You are not permitted to view the materials in this section of the website.”