CNC Machining

Generative Gear Grinding

At Milestone Gears, strength, precision and performance are forged in our world-class Heat Treatment Division. The facility features 28 Induction Hardening machines (Low, Medium & High Frequency), all equipped with SCADA-controlled systems for real-time process monitoring and uniform hardness profiles.

Our setup also includes 7 Sealed Quench Furnaces, 6 Gas Carburising Furnaces, 5 Press Quenches and specialized Cryogenic Treatment, Shot Peening and Glass Peening units — enabling us to deliver components with exceptional durability and fatigue resistance.

All processes are CQI-9 compliant and approved by global leaders such as Caterpillar, Kubota (Japan) and John Deere, reflecting our commitment to international standards.

Through advanced automation, digital temperature profiling and metallurgical validation, our Heat Treatment Division ensures every component achieves consistent microstructure, optimized case depth and long-term reliability — true to the Milestone promise of engineered excellence.

Gear Hobbing

At Milestone Gears, hobbing is not just a machining process — it’s a precision art backed by technology, discipline and passion.

We have a large installed base of Liebherr CNC Gear Hobbing Machines — LC 1500, 1000, 500, 250 and 200 — along with the high-speed Gleason 210H, multi-axis CNC controls, auto loading systems with real-time digital monitoring hobbing machines capable of cutting spur, helical and spline gears with extreme precision and repeatability.In-house fixture and tool design ensures flexibility for rapid new-product development.

Fully integrated SPC-based quality assurance and CMM validation for every gear batch

With our world-class infrastructure and skilled engineers, we consistently deliver gears that perform flawlessly, reinforcing our position as a trusted global transmission component partner across automotive, EV, construction, locomotive and wind energy sectors.

Internal Ring Gear Generation

At Milestone Gears, We are capable of producing Internal Ring Gears from all the available technologies: Scudding / Skiving, Shaping & Broaching

Scudding

Developed and patented in Germany, Scudding is a revolutionary gear generation process that allows continuous cutting of internal and external gears with exceptional speed, precision and surface finish — all without the interruptions of conventional shaping or broaching.

We currently house nine Profilator Scudding Machines, representing the largest concentration of Scudding technology in India. Our Profilator machines can produce internal ring gears up to 500 mm OD, with full capability for crowning, lead and profile corrections, ensuring flawless tooth geometry for planetary carriers, transmission housings and EV drive components.

We also possess hard scudding capability, enabling us to finish-hardened gears with micron-level accuracy — eliminating the need for separate grinding operations.

By integrating advanced Scudding technology into our manufacturing ecosystem, Milestone Gears has redefined productivity, precision and process reliability — making us the partner of choice for global OEMs in the automotive, EV and heavy-engineering sectors.

Internal Shaping

Equipped with advanced Lorenz 156 and Lorenz 400 CNC shaping machines, we deliver unmatched versatility and precision across a wide range of gear sizes and applications.

Our shaping capability covers components up to 1200 mm in diameter, enabling us to manufacture internal ring gears, spline profiles and precision gears used in planetary drives and other industrial gearboxes.

With CNC-controlled synchronization & automatic tool relieving, our shaping process ensures perfect tooth form, pitch accuracy and surface finish — even for intricate profiles where scudding, skiving & hobbing is not feasible.

Broaching

Equipped with high-performance broaching machines rated up to 110 tonnes, we are capable of producing internal and external profiles across a wide range of gear and shaft components. Our broaching systems — both vertical and horizontal configurations — ensure optimized force distribution, vibration-free operation and consistent finish even on complex geometries.

This plays a crucial role in machining internal splines, hubs, coupling components and transmission parts where tight dimensional control and smooth surface finish are critical.

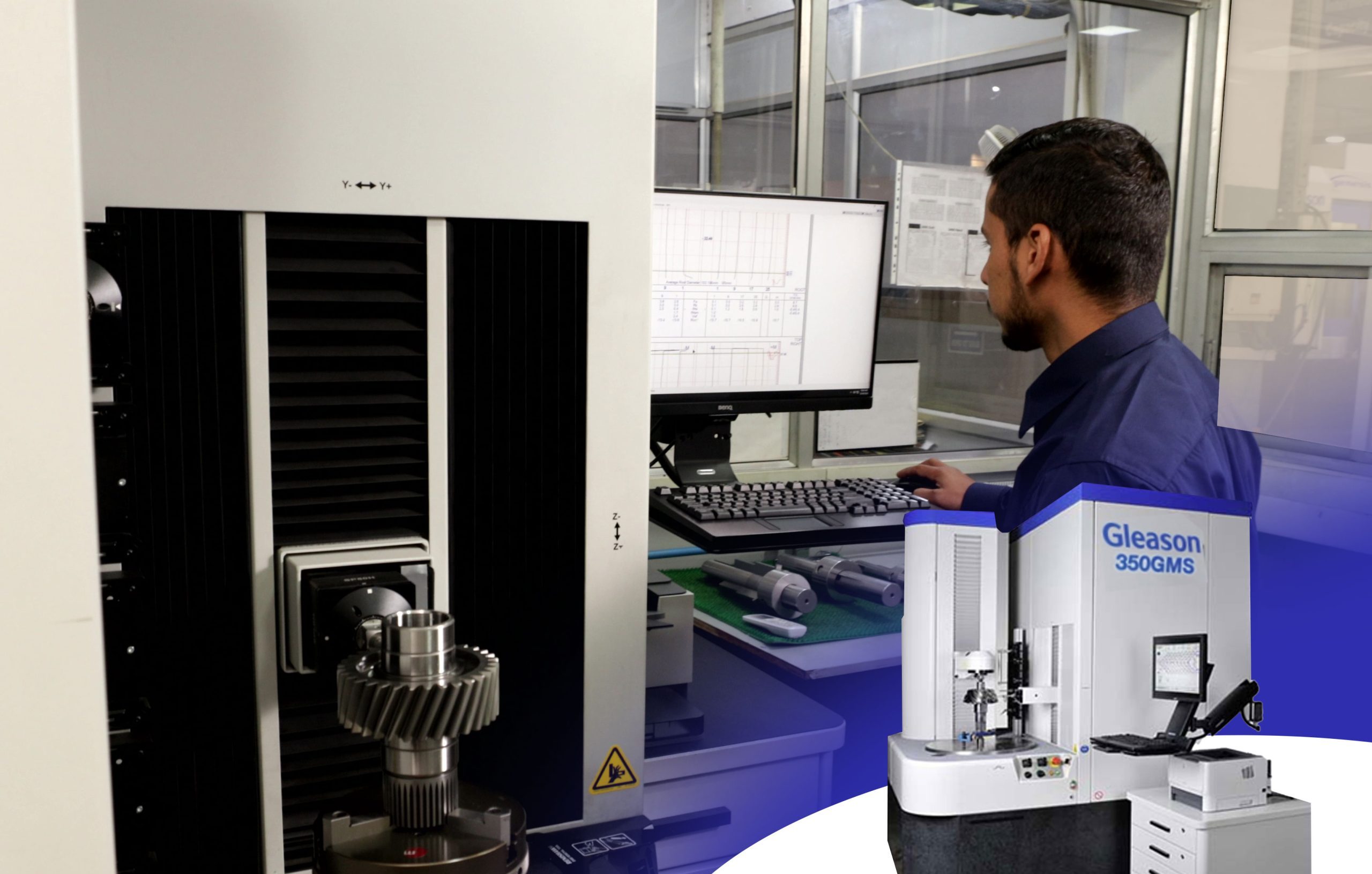

Bevel Gear Generator

We have the complete setup of the Gleason Bevel Gear Cutting 280 C machine, known worldwide for its reliability and performance. This cutting machine is engineered to produce Spiral, Hypoid and Straight bevel gear cutting with Coniflex cutting. Quality has always been imperative and every component produced is controlled by a closed-loop monitoring system.

This machine enables efficient and repeatable production of high-quality bevel gears for automotive, industrial and aerospace applications and it can produce DIN 5-7 class gear accuracy.

These machines are capable of producing and maintaining tooth topography within 20 micron/500 sum of square, enabling us to produce low NVH differential components well-suited for EVs and high-speed auto transmission.. The Gleason 280 C can cut bevel gears up to 280 Pitch diameter with a module range of 2-13 Module and a gear face width up to 58 mm. This machine can cut bevel gears using Face Milling and Face Hobbing methods.

CNC Turning & Blanking

At Milestone Gears, precision starts with machining. Our CNC Turning and Machining Division is equipped with advanced BFW Vertical Machining Centers (BT-50 & BT-30), Vertical Turning Centers (BVL 800H) and CNC Turning Centers from Mazak, LMW, ACE and Marshal.

With capacity to machine components up to 1,000 mm OD and 1,200 mm shaft length, we produce high-accuracy blanks for gears, shafts and axles across tractor, EV, locomotive and construction equipment segments.

Multi-axis CNC control, automatic tool changers and real-time process feedback ensure micron-level accuracy and consistency, laying the foundation for flawless downstream hobbing, grinding and assembly operations.

With Precihole Gun drilling Machines, we have capabilities to drill eccentric hole with a min dia of 5 mm upto 20mm and 1000 mm length accurately. Complex shafts are our forte!

375+ State-of-the-art

CNCs

Milestone Gears houses one of India’s largest and most advanced CNC machining infrastructures, reflecting its commitment to precision engineering and large-scale production capability.

We are first to introduce Skudding machines and have the highest number of German skiving machines in India.

Our Closed-loop Gleason 280C bevel gear robotic line ensures surgical-grade precision with every cut, enabling us to produce low NVH differential components well-suited for EVs and high-speed auto transmission.

Milestone Gears SAP integrated tool crib ensures lightning-fast tooling shifts complemented with in-house tool resharpening facility to maintain the manufacturing accuracies.

With state-of-the-art Liebherr and Gleason hobbing, Kenzaki shaping, Reishauer generative gear grinding with polishing stroke for DIN Class 4 precision, we machine gears up to 1,000-millimetre diameter and 300 kilogrammes.

Machining & Gear

Manufacturing Facilities

- With the highest number of German Skiving machines, we are among the leading manufacturers of ring gears in India.

- The comprehensive facility includes cutting-edge equipment for hobbing, shaving, generative gear grinding, skiving, broaching, shaping, gun drilling, external and internal grinding, turning, and VMC operations.

- Our wide range of CNC capabilities supports the machining of gears up to 1500 mm in diameter and rear axles or shafts up to 1500 mm in length.

- Production of gears of DIN Class 8 without grinding and gears of DIN Class 5 with grinding (post carburizing).

- Latest additions - Power Fly Skiving for internal gears and Klingenberg gear grinding machine.

Global Customers Base