Precision Components for Heavy-Duty Performance

Engineered for reliability. Manufactured at scale. Validated by leading OEMs.

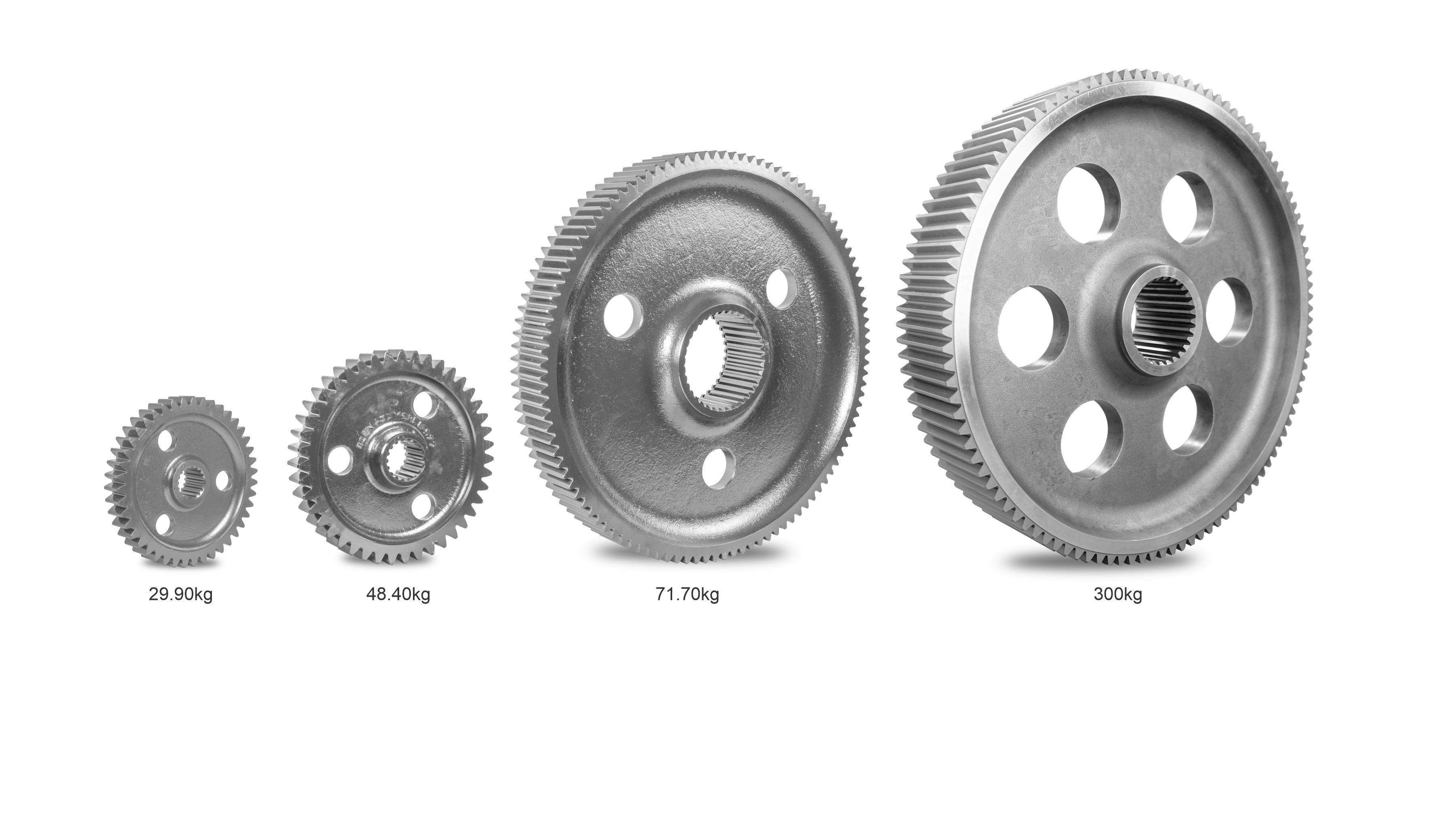

Bull Gears

- India’s Largest producer of tractor Bull gears

- Produced on Best in class NEW LIEBHERR 11-Axis Hobbing Machines

- Top of the line Reishauer Generative gear Grinding – Gear Quality upto Din class 4

- Dimensional Range: 20Kg to 200+Kg; Dia 300 – Dia 1000 mm; Module Upto 18

Available with traceable heat-treatment records and CMM inspection reports.

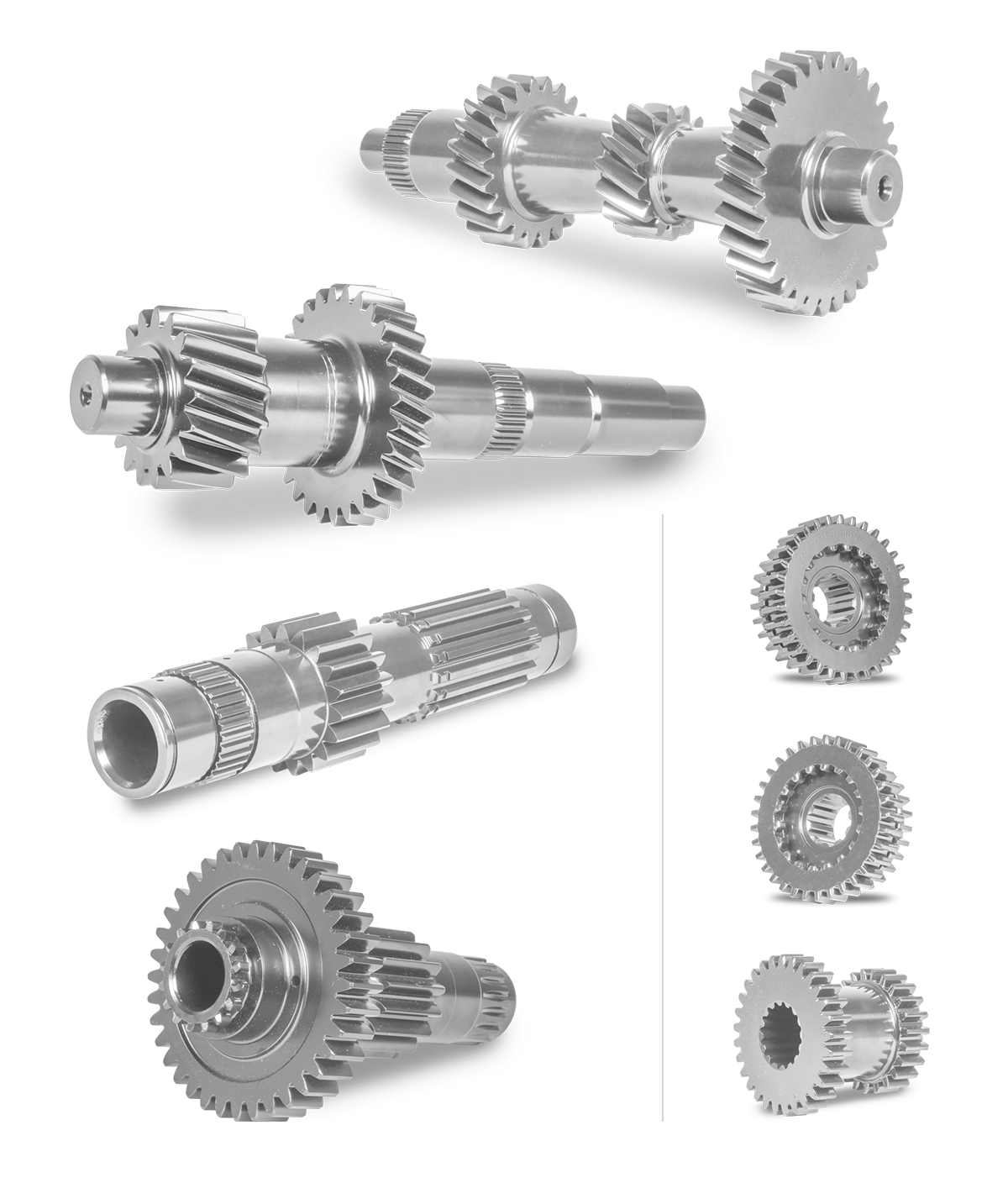

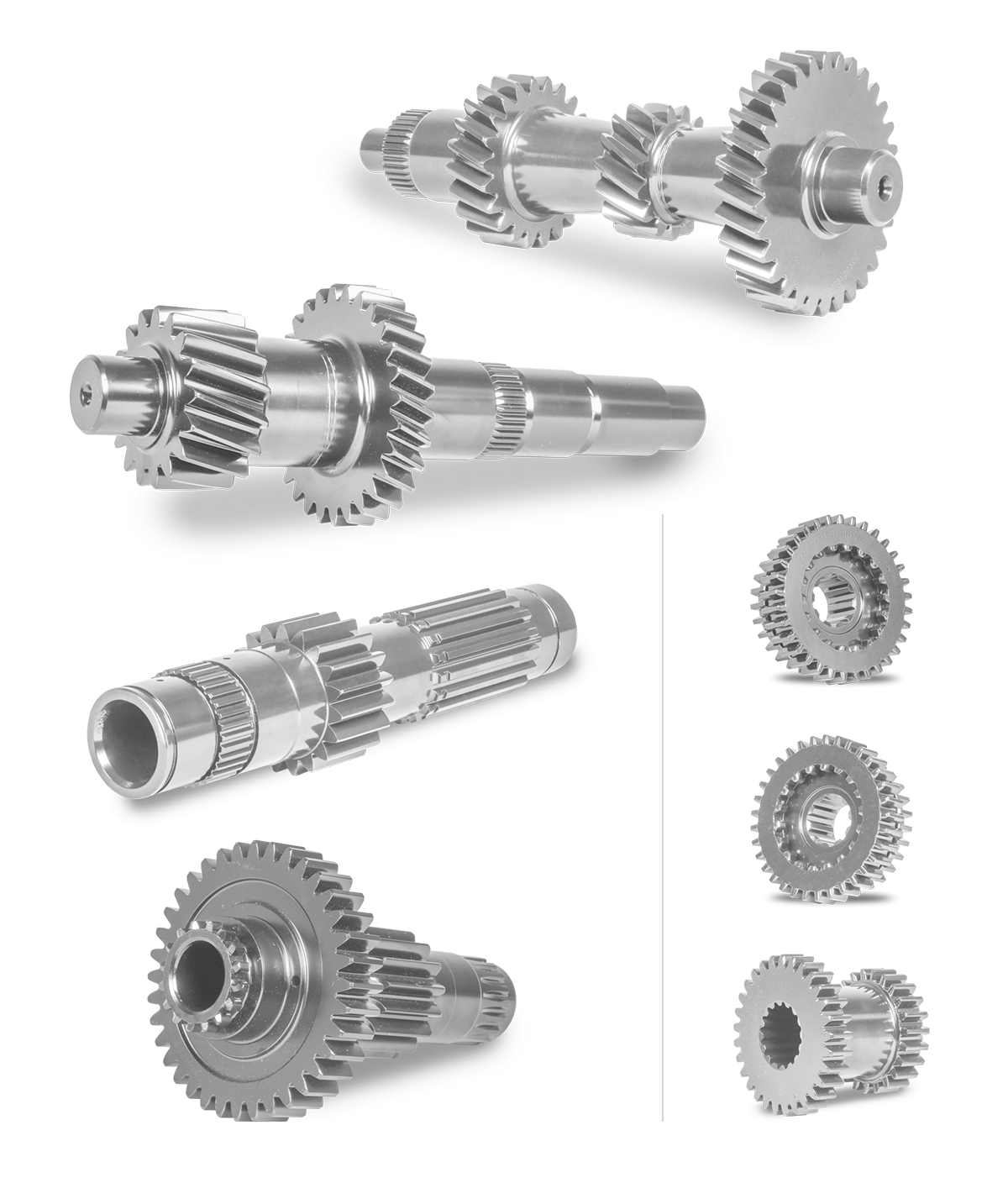

Transmission Gears & Transmission Shafts

- Produced on High End CNC Hobbing, Shaping & Shaping processes

- 11-Axis Tooth Roofing for complex & accurate Roofing operations

- Compound Gears & Shafts with blind hole broaching tech developed inhouse

- Internal & External Swaging

- Eccentric gun drilling upto 1000 mm length

Profile grinding and shot-peening options based on application.

Ground Gears & Ground Shafts

- Best in class Reishauer Generative Gear grinding Technology

- Gear quality upto DIN CLASS 4

- Inspected for Grinding Burns & Grinding Lead Twist

Cluster Gears & Shafts

- Installed capacity to manufacture 150,000 cluster gears and shafts annually.

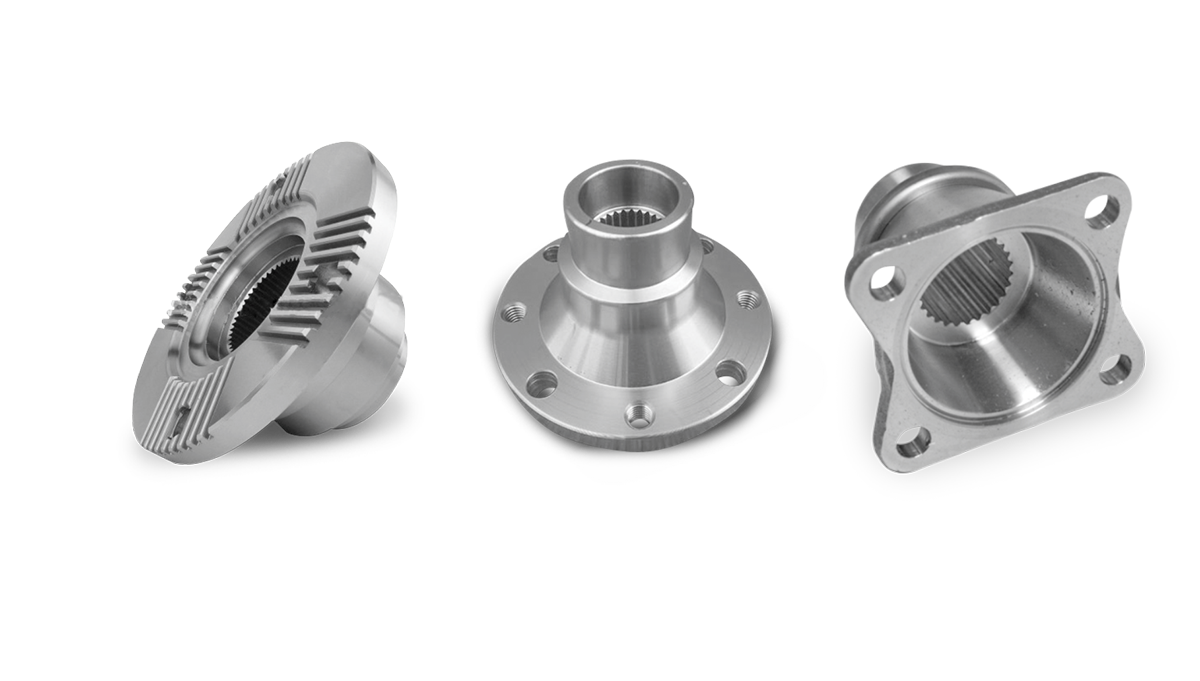

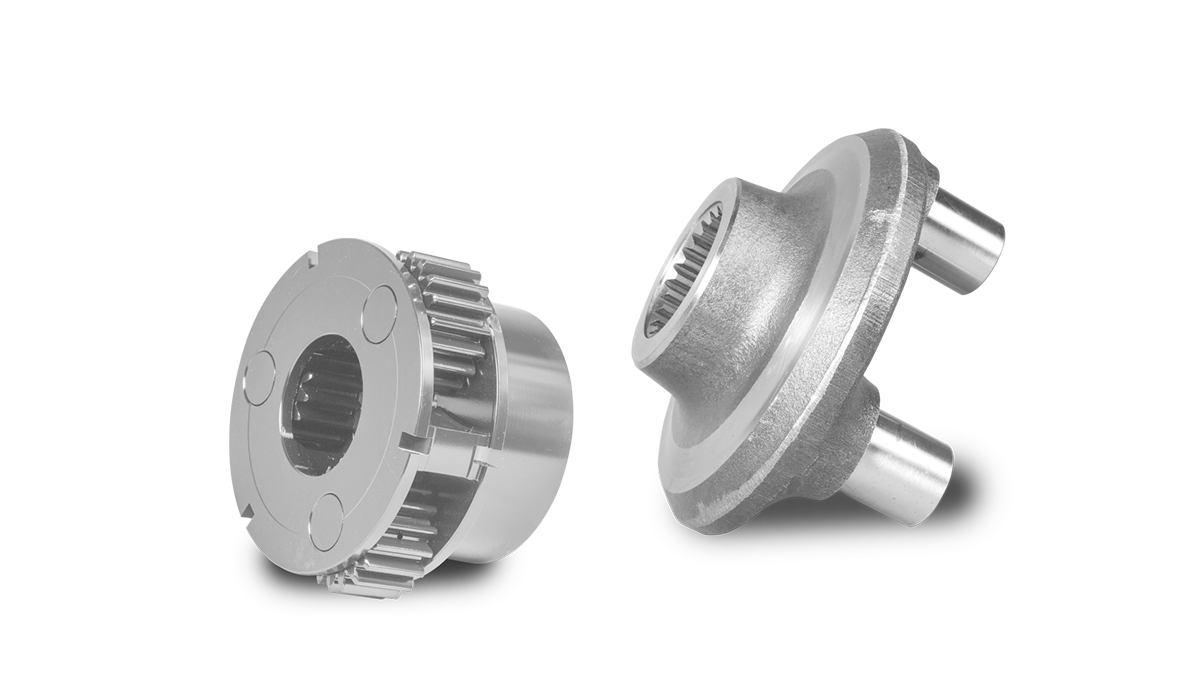

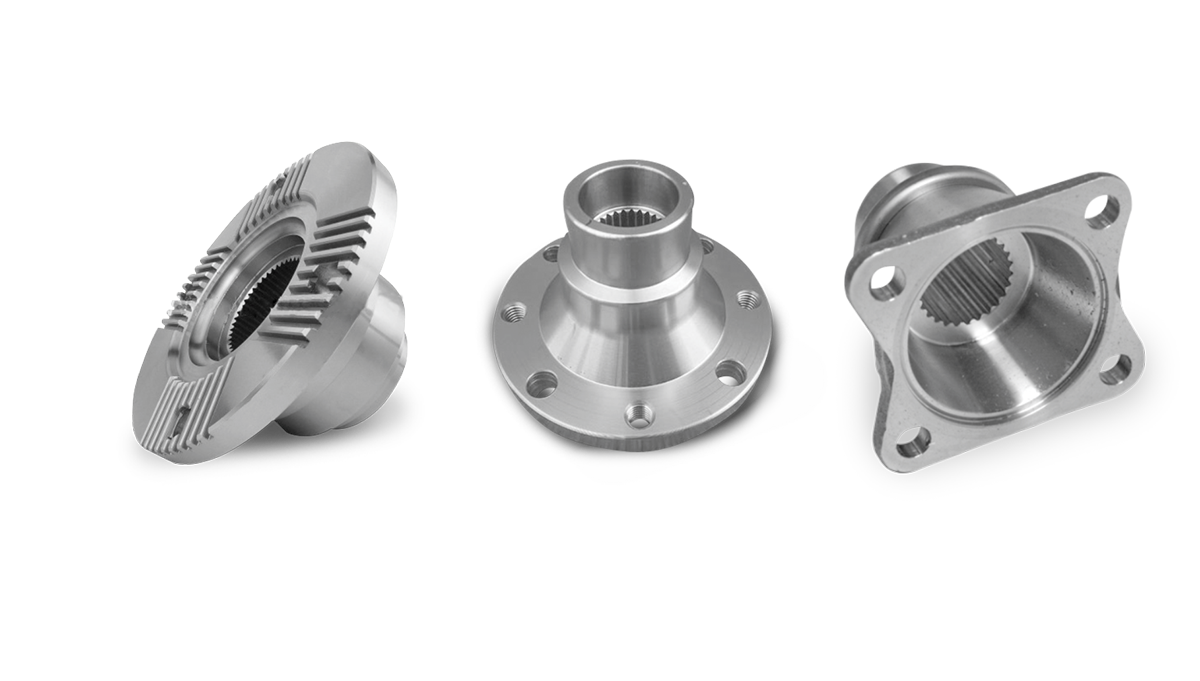

Companion Flanges

- Installed capacity to manufacture 72,000 companion flanges annually.

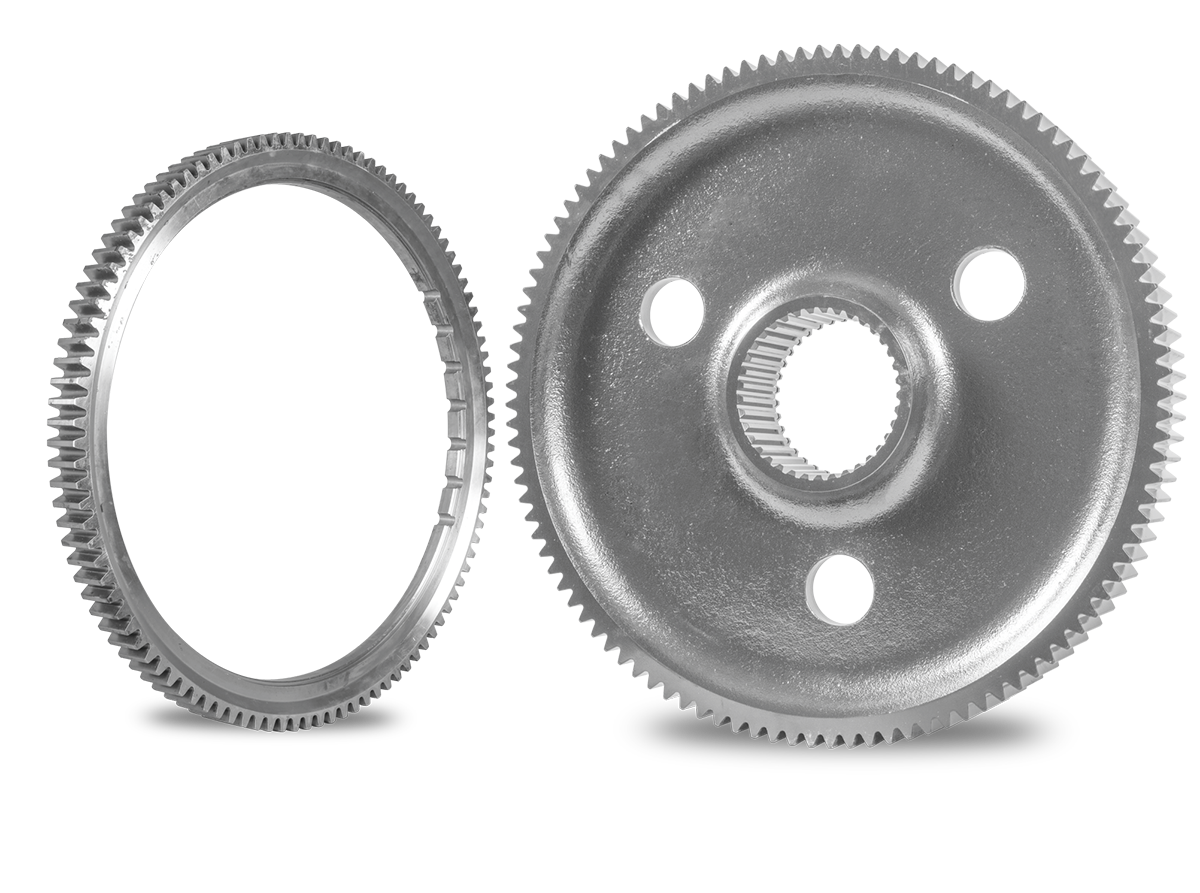

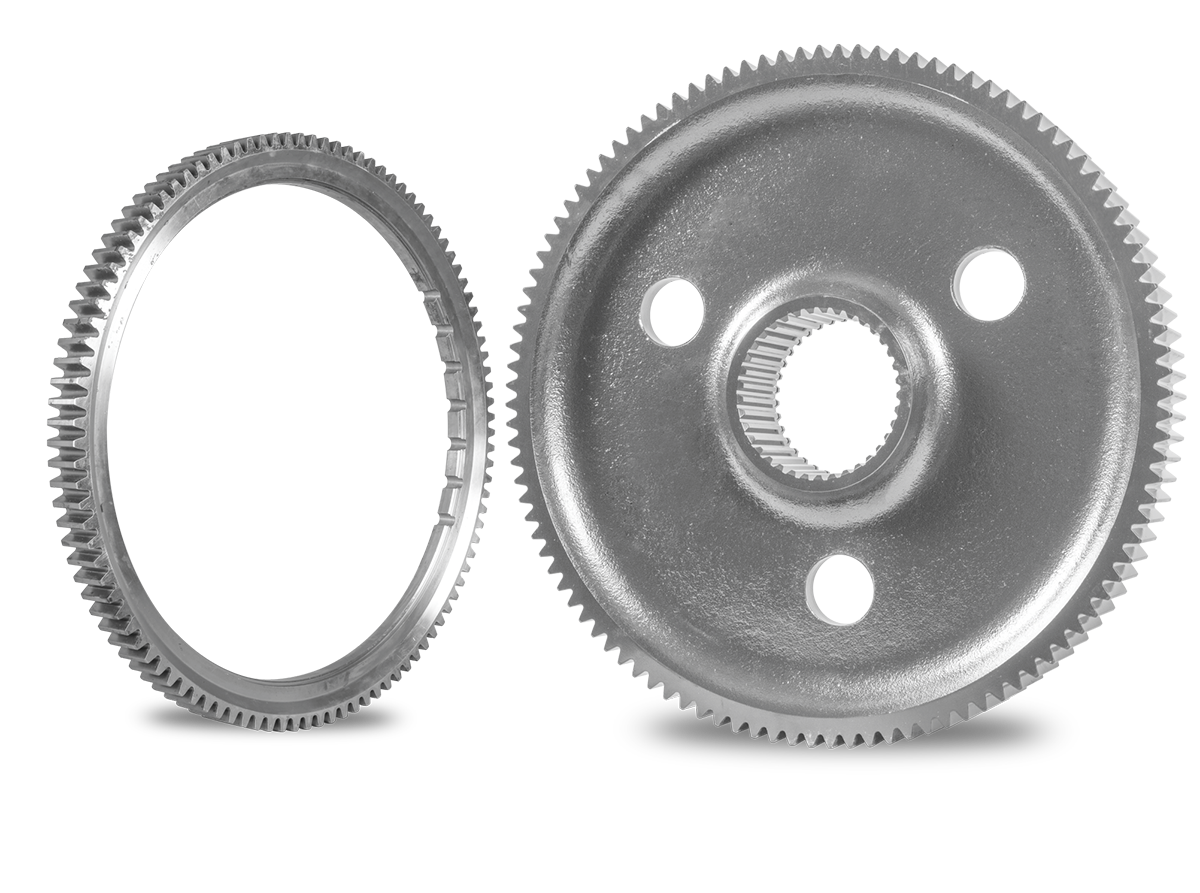

Internal Ring Gears

Milestone manufactures high-quality, precision internal ring gears. We’re enhancing the current production from 84,000 to 264,000 gears per annum.

- Amongst the Top 3 Ring Gears supplier for Domestic Tractor & CE

- Employing German Patented Skudding Technology enabling Lead & Profile corrections including Crown & Taper

- Helical Ring Gear & Compound ring gears in single setup

- Highest concentration of German Skudding machines in India

- Shaping & Broaching capability with upto 110T Vertical Broaching

- Carburized, Press Quenched, Induction Hardened & Nitrided

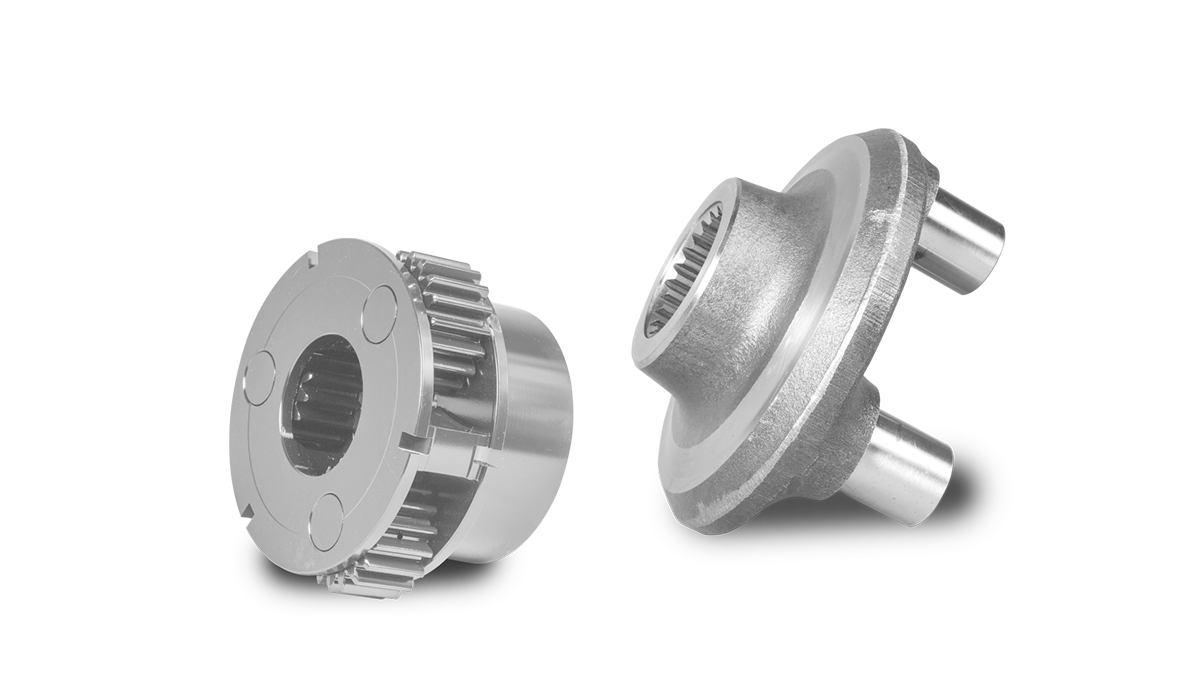

Epicyclic Reduction Assembly

- Installed capacity to manufacture 24,000 epicyclic reduction assembly parts annually.

Large Gears

- Installed capacity to manufacture 6,000 gears every year.

- Maximum gear diameter: 670 mm.

- Capability: Module 8.

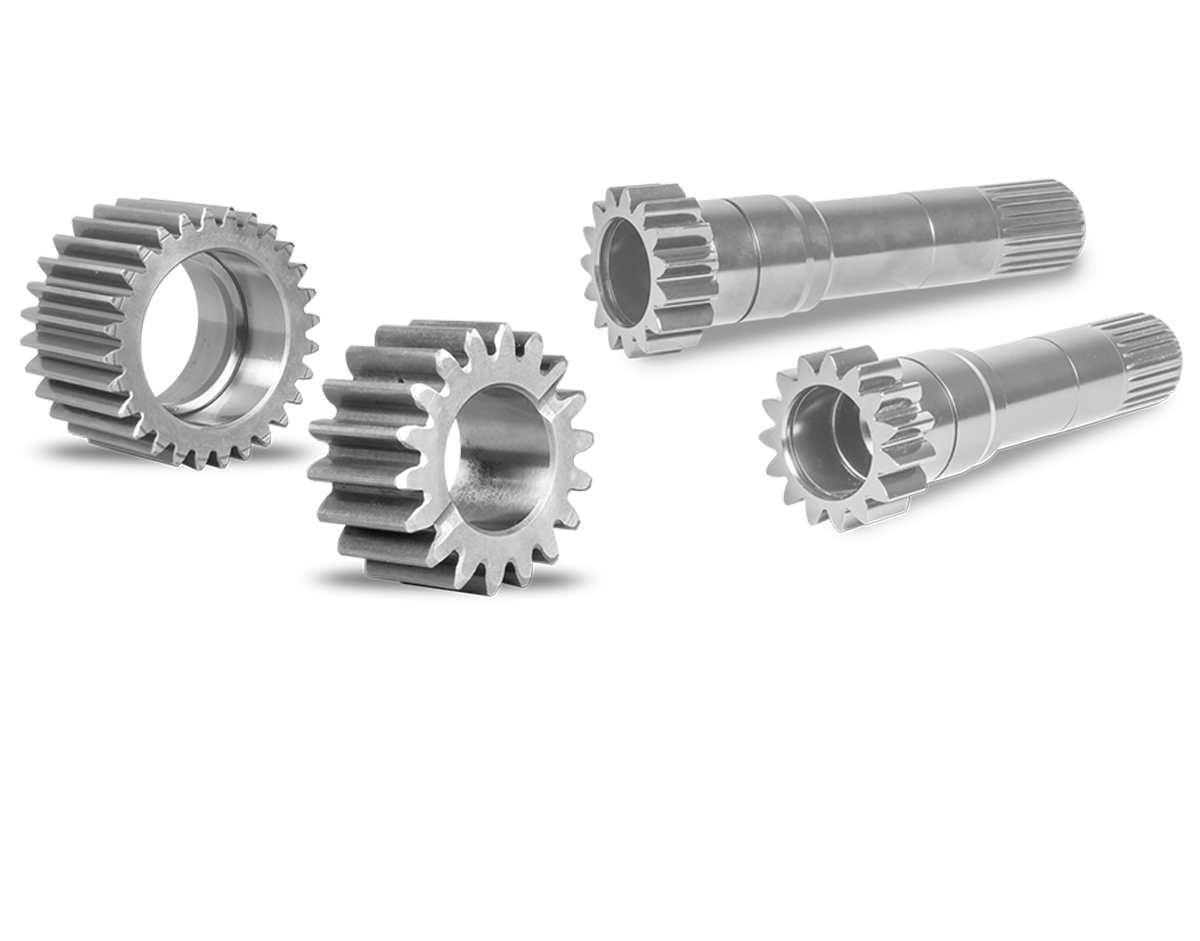

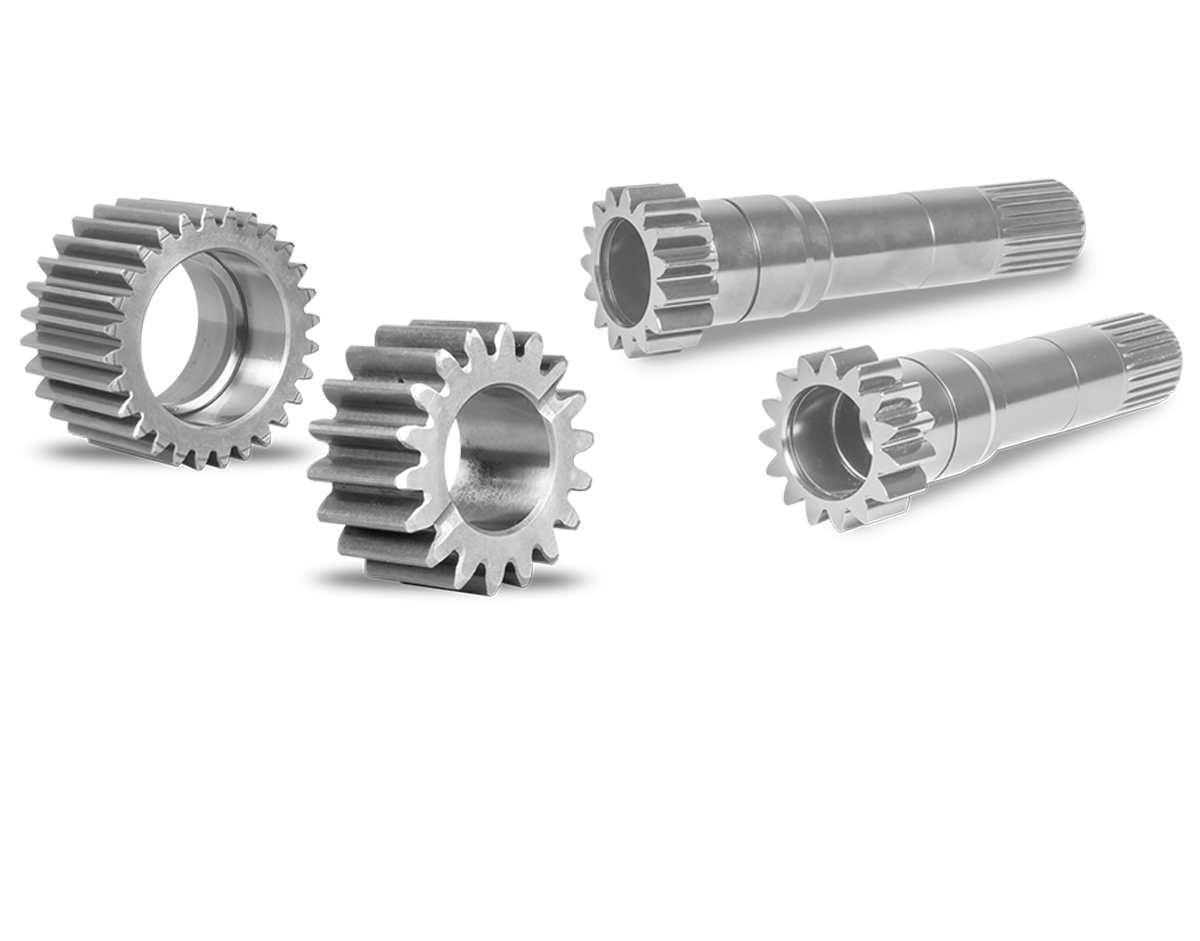

Planetary Gears, Sun Gears & Sun Shafts

Stronger, more compact and quieter sets designed to withstand demanding workloads. Installed capacity: 400,000 planetary gears & 180,000 sun gears (incl. plate carriers) annually.

Rear Axles

Our flagship product range.

- Amongst India’s Top 2 Tractor Rear Axle Producers

- Forged In-house || Induction Bar End Heaters || Auto Temperature Accept Reject mechanism

- 100% 3-Way Ultrasonically inspected defect free product

- MFG Range: Flange Dia Upto 320 mm, Length Upto 1500 mm, ECD: upto 12-14 mm

Spindles

Our flagship product range.

- Complete range of Front Spindles for Tractors & Construction Equipment

- Complex Shape & contouring on Press Forging

- Dedicated production set up with MAZAK twin-mill centres

Rockshaft & Induction Hardened Shafts

Highly durable rock shafts and induction-hardened PTO ground shafts.

- Installed capacity: 180,000 rock shafts & 240,000 PTO shafts annually.

- Max shaft length: 1270 mm (enhancing to 1500 mm).

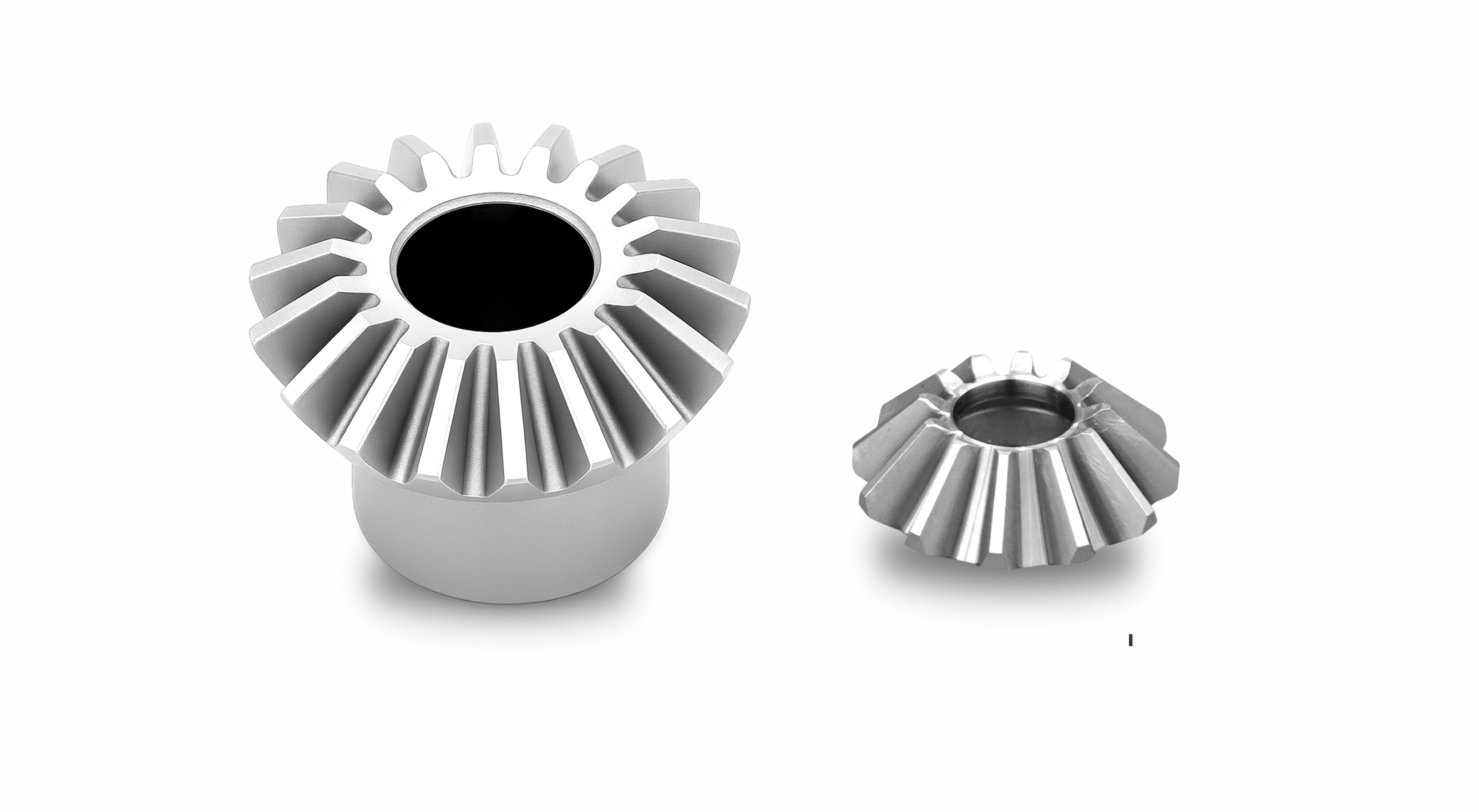

Cut Bevel Gears

High-integrity bevel sets for reliable torque transfer.

- Produced on Gleason 280C with closed loop feedback Robotic Line

- Low NVH Technology with Topography within 20 microns

- CTT maintained within ±5 Microns

Cluster Gears & Shafts

- Installed capacity to manufacture 150,000 cluster gears and shafts annually.

Companion Flanges

- Installed capacity to manufacture 72,000 companion flanges annually.

Epicyclic Reduction Assembly

- Installed capacity to manufacture 24,000 epicyclic reduction assembly parts annually.

Large Gears

- Installed capacity to manufacture 6,000 gears every year.

- Maximum gear diameter: 670 mm.

- Capability: Module 8.

Planetary Gears, Sun Gears & Sun Shafts

Stronger, more compact and quieter sets designed to withstand demanding workloads. Installed capacity: 400,000 planetary gears & 180,000 sun gears (incl. plate carriers) annually.